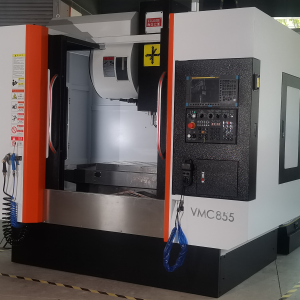

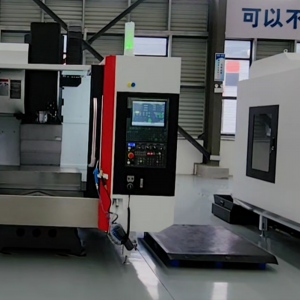

I ka ʻoihana hana i kēia lā,Nā mīkini wili CNCua hoʻohana nui ʻia ma muli o ko lākou mau pono nui e like me ke kiʻekiʻe kiʻekiʻe, kiʻekiʻe kiʻekiʻe, a me ke kiʻekiʻe o ka automation. Eia nō naʻe, i mea e hoʻohana pono ai i ka hana o nā mīkini wili CNC a hoʻokō i ka hana kiʻekiʻe a maikaʻi hoʻi, he mea koʻikoʻi ke koho ʻana i nā mea hana ʻoki. Ma keʻano he mea koʻikoʻi e pili pono ana i kaʻokiʻana,ʻo ka koho kūpono o nā meaʻokiʻoki e pili pono i ka maikaʻi a me ka hana pono o ka huahana hope. Ma muli o kēia, e komo kēia ʻatikala i nā wahi kūpono o ke koho ʻana i nā mea hanaNā mīkini wili CNC.

1、 Nā koi no ka ʻoki ʻana i nā mea hana i ka hana ʻana i ka mīkini milling CNC

Ma muli o kona pololei kiʻekiʻe, ka wikiwiki kiʻekiʻe, a me ke kiʻekiʻe o ka automation,Nā mīkini wili CNCua waiho mua i nā koi koʻikoʻi no nā mea hana i hoʻohana ʻia. I mea e hōʻoia ai i ka maikaʻi o ka mīkini a me ka hoʻomaikaʻi ʻana i ka hana ʻana, pono nā mea hana mīkini milling CNC i kēia mau ʻano:

(1) Pono a paʻa

ʻO ka mea mua, pono nā mea hana ʻoki i ka hilinaʻi kiʻekiʻe a me ka lōʻihi. I ke kaʻina hana machining mau oNā mīkini wili CNC, pono ka mea paahana e ku i ka ikaika oki ikaika a me na ukana wela no ka manawa loihi. Inā ʻaʻole lawa ka hilinaʻi o ka mea hana a haʻahaʻa paha kona lōʻihi, maʻalahi ia e hālāwai me nā pilikia e like me ka ʻaʻahu mua a me ka hāʻule ʻana o ka lihi, ʻaʻole ia e pili wale i ka maikaʻi machining akā alakaʻi pū i nā loli pinepine, hoʻonui i ka downtime hana, a hōʻemi i ka hana pono. No laila, ʻo ke koho ʻana i nā mea paahana me ke kūpaʻa ʻaʻahu maikaʻi, ka pale ʻana i ka hopena, a me ka paʻa ʻana o ka wela, a me ka hoʻolālā ʻana o ka mea hana pono, ʻo ia ke kī i ka hoʻomaikaʻi ʻana i ka hilinaʻi a me ka lōʻihi.

(2) Ka oolea a me ka ikaika

No ka hoʻokō ʻana i nā koi o ka hohonu ʻokiʻoki nui a me ka hānai wikiwiki i ka wā o ka mīkini paʻakikī, pono i ka mea hana ke ʻoi aku ka ikaika a me ka ikaika. ʻO ka hohonu o ka ʻokiʻoki nui a me ka hānai wikiwiki e hiki ai i ka mea hana ke kū i nā ikaika ʻoki nui. Inā ʻaʻole lawa ka paʻakikī o ka mea hana, hiki ke hoʻololi ʻia, e pili ana i ka pololei o ka mīkini; ʻAʻole lawa ka ikaika hiki ke alakaʻi i ka haki ʻana o ka mea hana a hiki i nā pōʻino palekana. No laila, i ke kaʻina o ka hoʻolālā ʻana a me ka hana ʻana, pono e lawe ʻia nā ana e like me ka hoʻonui ʻana i ke ʻano geometric o ka mea hana a me ke koho ʻana i nā mea ikaika kiʻekiʻe e hōʻoia i ka paʻakikī a me ka ikaika.

(3) Ka haki ʻana a me ka wehe ʻana i ka hana

He kūlana koʻikoʻi ka haki ʻana a me ka wehe ʻana i ka chip maikaʻi no ka hōʻoia ʻana i ka hana maʻamau o nā mea mīkini. Ma ke kaʻina hana oCNC wili, ka hana mau ʻana a me ka hōʻiliʻili ʻana o nā ʻāpana. Inā ʻaʻole hiki i ka mea hana ke haki a wehe pono i nā ʻāpana, e hoʻopili ʻia nā ʻāpana a puni ka mea hana a i ʻole ka mea hana, e hoʻopilikia ai i ka paʻa o ke kaʻina ʻoki a me ka hōʻino ʻana i ka mea hana a me ka mīkini. I mea e hoʻokō ai i ka wehe ʻana i nā puʻupuʻu maikaʻi, pono e hoʻolālā maikaʻi ʻia nā palena o ke ʻano o ka ʻoki ʻoki, ke kihi mua, a me ke kihi hope o ka mea hana. I ka manawa like, hiki i ke koho kūpono o ka ʻoki ʻana a me ka hoʻohana ʻana i ka wai ʻoki ke kōkua i ka hoʻomaikaʻi ʻana i ka hopena o ka lawe ʻana i ka chip.

(4) Hoʻokomo maʻalahi a hoʻoponopono

ʻO ka maʻalahi o ka hoʻonohonoho ʻana a me ka hoʻoponopono ʻana he mea nui ia no ka hoʻomaikaʻi ʻana i ka hana hana a me ka hōʻoia ʻana i ka pololei o ka mīkini. I ka hana ʻana o ka mīkini wili CNC, ma muli o ka hoʻololi pinepine ʻana i nā mea hana a me ka hoʻoponopono ʻana i ke kūlana mea hana, inā paʻakikī a paʻakikī ka hoʻonohonoho ʻana a me ka hoʻoponopono ʻana, e pau ka manawa. No laila, pono e koho ʻia nā mea hana ʻoki a me nā mea paʻa me ke ʻano maʻalahi, hoʻonohonoho pono a me ka hoʻonohonoho ʻana, a me ka hoʻoponopono kūpono e hoʻemi i ka hoʻololi ʻana o ka mea hana a me ka manawa hoʻoponopono, a hoʻomaikaʻi i ka helu hoʻohana o ka mīkini hana.

(5) Mea paahana ʻoki kiʻekiʻe

ʻO ke koho ʻana i nā mea paahana kiʻekiʻe ke kumu no ka hoʻomaikaʻi ʻana i ka hana hana. I kēia manawa, hoʻohana mau ʻia nā mea paahana noNā mīkini wili CNCe komo pū me ke kila kiʻekiʻe-wikiwiki, paʻa paʻa, uhi ʻia, seramika, cubic boron nitride, a me daimana. Loaʻa i nā ʻano mea hana like ʻole nā hiʻohiʻona hana, a pono e koho ʻia nā mea paahana kūpono ma muli o nā kumu e like me ke ʻano o ka mea hana, ka ʻenehana hana, a me nā kūlana ʻoki. No ka laʻana, ʻo nā mea hana ʻoki kila kiʻekiʻe ka paʻakikī a me ka grindability, e kūpono ana ia no ka hana ʻana i nā ʻāpana paʻakikī a me ka ʻoki haʻahaʻa; ʻO nā mea hana paʻa paʻa paʻa paʻa paʻa kiʻekiʻe a me ke kūpaʻa maikaʻi ʻana, e kūpono ana ia no ka ʻoki kiʻekiʻe a me ka mīkini paʻakikī; Hoʻomaikaʻi hou aku nā mea hana ʻoki i uhi ʻia i kā lākou hana ma ka uhi ʻana i ko lākou ʻili me kahi pale pale pale a me ka wela kiʻekiʻe, e kūpono ana iā lākou no nā kūlana ʻoki like ʻole.

2、 Ka hoʻokaʻawale ʻana i nā mea hana mīkini wili CNC

Aia nā ʻano like ʻole oMīkini wili CNCnā mea hana, hiki ke hoʻokaʻawale ʻia i nā ʻano like ʻole e like me nā kūlana hoʻohālikelike like ʻole. ʻO kēia nā ʻano hoʻohālikelike maʻamau:

(1) Hoʻokaʻawale ʻia e ke ʻano mea hana

Nā mea hana ʻoki hoʻohui

ʻO nā mea hanaʻoki i hoʻohuiʻia e pili ana i nā mea hana i hanaʻia e like me ka mea hana a me ka shank, e like me ka wili hope, drills, etc. He kūpono ia no ka hana ʻana i nā ʻāpana me nā ʻano maʻalahi a me nā koi kikoʻī kiʻekiʻe.

Mea hana ʻoki ʻoki ʻia

ʻO nā mea hana ʻoki i hoʻopili ʻia he mau mea hana e hoʻokomo ai i ka lau a i ʻole nā niho ma luna o ke kino ʻoki, e like me nā wili hope inlaid, nā mea hoʻohuli, a me nā mea ʻē aʻe.

ʻAno kūikawā o nā mea hana ʻoki

ʻO nā meaʻokiʻokiʻano kūikawā e pili ana i nā mea hana i hanaʻia no ka hoʻokōʻana i kekahi mau koi hana kūikawā, e like me nā mea hana hana, nā mea hana hui, a me nā mea'ē aʻe. Hiki i nā mea hana ʻoki hui ke hoʻopau i nā ʻanuʻu hana he nui i hoʻokahi kaʻina ʻokiʻoki, e like me ka wili ʻana a me ka wili ʻana i nā mea hana ʻoki composite, nā mea ʻoki a me ka milling composite ʻokiʻoki, etc.

(2) Hoʻokaʻawale ʻia e ka mea paahana

ʻO nā mea hana ʻoki kila kiʻekiʻe

ʻO ke kila wikiwiki kiʻekiʻe ke ʻano o ke kila kila kiʻekiʻe i loaʻa ka nui o nā mea hoʻohuihui e like me tungsten, chromium, a me vanadium. Loaʻa i nā mea hana ʻoki kila kiʻekiʻe ka paʻakikī a me ka grindability, a hiki ke pale i nā ukana hopena nui. Hoʻohana pinepine ʻia lākou e hana i nā ʻāpana me nā ʻano paʻakikī a me nā koi kikoʻī kiʻekiʻe, e like me nā drills, taps, milling cutters, a me nā mea ʻē aʻe.

ʻO ke kila kiʻekiʻe kiʻekiʻe o ke ao holoʻokoʻa: ʻO kona paʻakikī paʻakikī mai 62 a 69HRC, loaʻa iā ia ke kūpaʻa ʻaʻahu, ka ikaika kiʻekiʻe a me ka paʻakikī, a ʻo ka wikiwiki o ka ʻoki ʻana ʻaʻole ʻoi aku ka kiʻekiʻe ma mua o 45 a 60m / min, ʻaʻole kūpono no ka ʻoki kiʻekiʻe.

ʻO ke kila kiʻekiʻe kiʻekiʻe ka hana kiʻekiʻe: He kila kila me ke kūpaʻa wela kiʻekiʻe a me ke kūpaʻa ʻaʻahu i loaʻa ma ka hoʻonui ʻana i ka ʻike o ke kalapona a me ka vanadium ma ke kumu o ke kila kiʻekiʻe. ʻO ke kila kila kiʻekiʻe ka hana kiʻekiʻe he ʻulaʻula maikaʻi, a hiki ke mālama i ka paʻakikī o 60HRC ma 620-660 ℃. ʻO kona lōʻihi he 2-3.5 mau manawa ma mua o ke kila kiʻekiʻe kiʻekiʻe. Hoʻohana mau ʻia ke kila kiʻekiʻe kiʻekiʻe no ka hana paʻakikī i nā mea mīkini e like me nā ʻāpana wela wela a me nā ʻāpana titanium.

ʻO nā mea hana ʻoki paʻa paʻa

Hana ʻia ka paʻa paʻa e ka pauka metallurgy kaʻina me ka hoʻohana ʻana i ka paʻakikī kiʻekiʻe, nā carbide metala kiʻekiʻe (e like me ka tungsten carbide, titanium carbide, etc.) pauka a me nā mea hoʻopaʻa (e like me ka cobalt, nickel, etc.). ʻO nā mea hana paʻa paʻa paʻa i nā hiʻohiʻona o ka paʻakikī kiʻekiʻe, ke kūpaʻa maikaʻi o ka lole, a me ke kūpaʻa wela kiʻekiʻe, me ka wikiwiki o ka ʻoki ʻana o 100-300m / min, kūpono no ka ʻoki kiʻekiʻe a me ka mīkini paʻakikī. Hiki ke hoʻokaʻawale ʻia nā mea hana ʻoki paʻa paʻa i ka tungsten cobalt (YG), tungsten titanium cobalt (YT), a me ka tungsten titanium tantalum (niobium) cobalt (YW) ma muli o kā lākou haku mele a me ka hana.

Tungsten cobalt (YG) paʻa paʻa: YG paʻa paʻa i loaʻa i ka kobalt kiʻekiʻe a me ka paʻakikī maikaʻi, e kūpono ia no ka hana ʻana i nā mea palupalu e like me ka hao a me nā metala non-ferrous.

Tungsten titanium cobalt (YT) paʻa paʻa: YT paʻa paʻa i ka titanium maʻiʻo kiʻekiʻe, maikaʻi ka paʻakikī a me ke kūpaʻa ʻaʻahu, a kūpono no ka hana ʻana i nā mea plastik e like me ke kila.

ʻO Tungsten titanium tantalum (niobium) cobalt (YW) paʻa paʻa: YW paʻa paʻa hoʻohui i nā mea maikaʻi o YG a me YT paʻa paʻa, me ka paʻakikī kiʻekiʻe, ke kūpaʻa ʻana, ka wela, a me ka paʻakikī, kūpono no ka hana ʻana i nā mea like ʻole, ʻoi aku ka paʻakikī i nā mea mīkini e like me ke kila kila a me ke kila wela.

ʻO nā mea hana ʻoki i uhi ʻia

Hoʻopiliʻia nā mea hanaʻoki i hoʻopiliʻia me kahi papa o nā mea hoʻopili pale a me ka wela kiʻekiʻe, e like me TiC, TiN, Al2O3, a me nā mea'ē aʻe, ma kaʻili o ka paʻa paʻa a iʻole nā mea hana kila kiʻekiʻe. Hiki i nā mea hana ʻoki ʻoki ke hoʻomaikaʻi nui i ka paʻakikī o ka ʻili, ke kūpaʻa a me ka pale wela o nā mea ʻoki, a hoʻonui i ko lākou ola lawelawe. He kūpono nā mea hana ʻoki ʻoki no nā kūlana ʻoki like ʻole, ʻoi aku ka wikiwiki o ka ʻoki a me ka ʻoki maloʻo.

ʻO nā mea hana ʻoki seramika

ʻO ka nui o nā mea hana seramika e like me ka alumina (Al2O3) a me ka silicon nitride (Si3N4), i hoʻopaʻa ʻia i nā wela kiʻekiʻe. Loaʻa i nā mea hana ʻoki Ceramic nā mea maikaʻi e like me ka paʻakikī kiʻekiʻe, ke kūpaʻa maikaʻi i ka ʻaʻahu, ke kūpaʻa wela kiʻekiʻe, a me ke kūpaʻa kemika maikaʻi. Hiki i ka wikiwiki o ka ʻoki ʻana ke piʻi i ka 500-1000m / min, e hoʻolilo iā lākou i kūpono no ka ʻoki kiʻekiʻe a me ka mīkini pololei. Eia nō naʻe, ʻoi aku ka maikaʻi o nā mea hana ʻoki ceramic a me ke kūpaʻa maikaʻi ʻole. I ka hoʻohana ʻana iā lākou, pono e uku ʻia i ka pale ʻana i nā ukana hopena.

ʻO nā mea hana ʻoki cubic boron nitride

ʻO Cubic boron nitride (CBN) he mea hoʻoheheʻe ʻia me ka paʻakikī lua wale nō i ke daimana. Loaʻa i nā mea hana ʻokiʻoki cubic boron nitride e like me ka paʻakikī kiʻekiʻe, ke kūpaʻa ʻaʻahu maikaʻi, ke kūpaʻa wela kiʻekiʻe, a me ke kūpaʻa kemika maikaʻi. Hiki i ka wikiwiki o ka ʻoki ʻana ke piʻi i ka 1000-2000 m / min, e hoʻolilo iā lākou i kūpono no ka ʻokiʻoki kiʻekiʻe a me ka mīkini pololei o nā mea paʻakikī kiʻekiʻe e like me ke kila kinai a me ka hao hoʻoheheʻe.

Nā mea hana ʻoki daimana

ʻO ka daimana ka mea ʻoi loa ka paʻakikī o ke ʻano, a ʻo nā mea hana ʻoki daimana he paʻakikī kiʻekiʻe loa, ke kūpaʻa ʻana, a me ka conductivity thermal. Hiki i ka wikiwiki o ka ʻokiʻoki ke piʻi i 2000-5000m / min, e hoʻolilo iā lākou i kūpono no ka ʻoki kiʻekiʻe kiʻekiʻe a me ka mīkini pololei o nā mea non-ferrous a me nā mea ʻole. Eia nō naʻe, he pipiʻi nā mea hana ʻoki daimana a ʻaʻole kūpono no ka hoʻoponopono ʻana i nā mea metala i hoʻokumu ʻia i ka hao, no ka mea, e hana ana nā daimana i nā hopena kemika me ka hao i nā wela kiʻekiʻe.

3、 Ke koho ʻana i nā mea hana ʻoki no nā mīkini wili CNC

Aia nā ʻano mea hana like ʻole i hoʻohana ʻia no ka mīkini CNC, kēlā me kēia me kāna mau hiʻohiʻona hana kūikawā a me ka hoʻohana ʻana. Ke koho ʻana i nā mea paahana, pono e noʻonoʻo pono i nā mea e like me ke ʻano o ka mea hana, ka ʻenehana hana, nā kūlana ʻokiʻoki, a me nā mea ʻē aʻe, i mea e koho ai i ka mea hana pono.

(1) Nā hōʻailona hana o ka ʻoki ʻana i nā mea paahana no ke ʻoki metala

ʻO ka mea ʻoki mea hana no ka ʻoki ʻana i ka metala maʻamau e loaʻa i kahi ʻano o nā hōʻailona hana, ma waena o ka paʻakikī, ka ikaika, ka ʻulaʻula ʻulaʻula, ka thermal conductivity, etc.

ʻO ka paʻakikī ka hiki i nā mea paahana ke kū'ē i kaʻaʻahu, aʻo ke kiʻekiʻe o ka paʻakikī,ʻo kaʻoi aku o ka paleʻana o ka mea hana. ʻO ka ikaika ka hiki o nā mea paahana ke pale aku i ka haʻihaʻi a me ka deformation, a hiki i nā mea hana ikaika kiʻekiʻe ke kū i nā ʻoki koʻikoʻi. ʻO ka paʻakikī ʻulaʻula e pili ana i ka hiki o nā mea paahana e mālama i ka paʻakikī i nā wela kiʻekiʻe, a ʻo nā mea hana me ka ʻulaʻula maikaʻi e kūpono i ka ʻoki kiʻekiʻe. Hoʻopili ka thermal conductivity i ka hopena wela o nā mea hana ʻoki. Hiki i nā mea hana me ka hana wela maikaʻi ke hoʻololi koke i ka ʻoki ʻana i ka wela a hoʻemi i ka ʻaʻahu wela o nā mea hana.

(2) Mea paahana kūpono

ʻO ka mea paahana kūpono e loaʻa i ka paʻakikī a me ka ikaika, a me ka ʻulaʻula maikaʻi, ka conductivity thermal, ke kūpaʻa a me ka paʻakikī. Eia nō naʻe, ma nā noi kūpono, paʻakikī ka loaʻa ʻana o kahi mea paahana e hoʻokō pono ai i nā koi āpau, no laila pono ke kaupaona a koho ʻia e like me nā kūlana hana kikoʻī.

(3) Nā mea paahana ʻoki maʻamau i hoʻohana ʻia i nā hana pono

Ma ka hana hoʻomaʻamaʻa, hoʻohana nui ʻia nā mea hana ʻoki paʻa paʻa paʻa a me nā mea hana ʻoki paʻa paʻa ma muli o kā lākou hana piha piha.

ʻO nā mea hana ʻoki paʻa paʻa paʻa paʻa kiʻekiʻe a me ke kūpaʻa ʻana, hiki ke hoʻololi i nā koi o ka ʻoki kiʻekiʻe a me ka mīkini paʻakikī. ʻO nā mea hana ʻoki paʻa paʻa paʻa i uhi ʻia, ma ke kumu o nā mea ʻoki ʻoki paʻa paʻa, e hoʻomaikaʻi hou i kā lākou hana a hoʻonui i ko lākou ola lawelawe ma ka uhi ʻana iā lākou me kahi ʻāpana o ka pale ʻana a me ka wela wela.

No kekahi mau mea paʻakikī i ka mīkini, e like me nā ʻāpana wela kiʻekiʻe, nā alloys titanium, a me nā mea ʻē aʻe. ʻO nā mea hana ʻokiʻoki cubic boron nitride he paʻakikī kiʻekiʻe a me ka ʻulaʻula maikaʻi, hiki ke ʻoki pono i nā mea paʻakikī kiʻekiʻe; ʻO nā mea hana ʻoki daimana he paʻakikī kiʻekiʻe loa a me ka conductivity thermal, e kūpono ana ia no ka mīkini pololei ʻana o nā mea non-ferrous a me nā mea ʻole.

ʻOiai ʻaʻole paʻakikī a paʻa ʻole nā mea hana ʻoki kila kiʻekiʻe e like me nā mea hana ʻoki paʻa paʻa, aia nō kekahi mau noi i ka hana ʻana i nā ʻāpana ʻano paʻakikī a me ka ʻoki haʻahaʻa haʻahaʻa ma muli o ko lākou paʻakikī maikaʻi a me ka grindability.

He paʻakikī kiʻekiʻe ka paʻakikī o nā mea hana ʻoki keramika a me ke kūpaʻa maikaʻi ʻana, akā palupalu lākou a kūpono no ka ʻoki kiʻekiʻe a me ka mīkini pololei.

4、 ʻO nā kumu hoʻohālikelike o ke koho ʻana i nā mea hana no nā mīkini wili CNC

Ke koho ʻana i nā mea hana mīkini wili CNC, pono e noʻonoʻo nui ʻia nā mea aʻe:

(1) Ka hana mīkini hana

ʻO nāʻano likeʻole a me nā kiko'ī o nā mīkini mīkini CNC he mauʻano hana likeʻole, e like me ka wikiwiki o ka spindle, ka hānai hānai, ka mana, ka torque, a me nā mea'ē aʻe. No ka laʻana, no nā mīkini wili kiʻekiʻe, pono e koho ʻia nā mea hana ʻoki kūpono no ka ʻoki kiʻekiʻe, e like me nā mea hana paʻa paʻa i uhi ʻia, nā mea hana seramika, a pēlā aku; No nā mīkini wili mana kiʻekiʻe, hiki ke koho ʻia nā mea hana ʻoki me ka ikaika kiʻekiʻe a me ka ʻoʻoleʻa, e like me nā mea hana ʻoki paʻa paʻa.

(2) Mea hana mea hana

He hopena koʻikoʻi ka hana o nā mea hana i ke koho ʻana i nā mea hana. Loaʻa i nā mea hana mea hana like ʻole ka paʻakikī, ka ikaika, ka paʻakikī, ka conductivity thermal, a me nā mea ʻē aʻe. I ka hana ʻana i nā mea plastik e like me ke kila, ʻoi aku ka maikaʻi o ke koho ʻana i ka YT type hard alloy hard tool a i ʻole nā mea hana ʻoki i uhi ʻia; I ka wā e hana paʻakikī ai i nā mea mīkini e like me nā alloys wela kiʻekiʻe a me nā alloys titanium, pono e koho ʻia nā mea ʻoki boron nitride cubic a i ʻole nā mea hana ʻoki daimana.

(3) Papahana hana

ʻO ke ʻano o ka papahana mīkini (e like me ka mīkini paʻa, semi precision machining, precision machining) a me nā ʻāpana ʻokiʻoki (e like me ka wikiwiki o ka ʻoki ʻana, ka nui o ka hānai ʻana, ka hohonu ʻoki) pili pū i ke koho ʻana i nā mea hana ʻoki. Ke koho ʻia ka mīkini ʻokiʻoki, nā mea hana ʻoki me ka ikaika kiʻekiʻe a me ka ʻoʻoleʻa e hiki ke kū i nā ikaika ʻoki nui e koho ʻia, e like me nā mea hana ʻoki paʻa paʻa; Ke koho ʻia nā mea hana me ka pololei kiʻekiʻe a me ka maikaʻi o ka ʻili, e like me nā mea hana paʻa paʻa i uhi ʻia a i ʻole nā mea hana seramika.

(4) Ka nui oki

Hoʻoholo pololei ka nui o ka ʻoki ʻoki i ka ikaika ʻoki a me ka ʻoki ʻana i ka wela i lawe ʻia e ka mea hana. I ka hana ʻana me ka nui o ka ʻoki ʻana, pono e koho ʻia nā mea hana me ka ikaika kiʻekiʻe a me ke kūpaʻa wela maikaʻi; I ka hana ʻana me nā mea ʻoki liʻiliʻi, hiki ke koho ʻia nā mea hana me ka paʻakikī kiʻekiʻe a me ke kūpaʻa maikaʻi.

5、 Nā ʻanuʻu a me nā ala no ke koho ʻana i nā mea hana ʻoki no nā mīkini wili CNC

Ke koho ʻana i nā mea hana mīkini wili CNC, hiki ke hahai ʻia kēia mau ʻanuʻu:

(1) E hoʻoholo i nā pono hana

ʻO ka mea mua, pono e wehewehe i ke ʻano, ka nui, nā koi kikoʻī, nā koi o ka maikaʻi o ka ʻili, a me nā ʻenehana hana (e like me ka mīkini paʻakikī, ka mīkini semi precision, a me ka mīkini pololei) o nā ʻāpana i hana ʻia.

(2) E noʻonoʻo i ka mea o ka mea hana

E noʻonoʻo i ka hana o ka mea hana, me ka paʻakikī, ka ikaika, ka paʻakikī, ka thermal conductivity, a me nā mea ʻē aʻe, e hoʻoholo ai i ka mea paahana kūpono.

(3) E koho i ke ʻano mea hana

E like me nā koi hana a me nā mea hana hana, koho i ke ʻano kūpono o ka mea hana, e like me nā wili hope, drills, boring cutters, etc.

(4) E hoʻoholo i nā ʻāpana mea hana

E hoʻoholo i ke anawaena, ka lōʻihi, ka helu o nā ʻaoʻao, ke kihi helix, ke kihi alakaʻi, ka ʻaoʻao hope, a me nā ʻāpana ʻē aʻe o ka mea ʻoki e pili ana i ka ʻoki ʻana a me ka hana mīkini.

(5) E koho i nā hōʻailona mea hana ʻoki a me nā mea hoʻolako

Ma hope o ka hoʻoholo ʻana i ke ʻano a me nā palena o nā mea hana ʻoki, koho i nā hōʻailona kaulana a me nā mea hoʻolako hilinaʻi e hōʻoia i ka maikaʻi o nā mea hana a me ka lawelawe ma hope o ke kūʻai aku.

6、 Hoʻohana a mālama i nā mea hana mīkini wili CNC

ʻO ke koho ʻana i ka hāmeʻa kūpono ʻo ia wale nō ka hana mua, a ʻo ka hoʻohana pono ʻana a me ka mālama ʻana i ka hāmeʻa he mea koʻikoʻi ia no ka hōʻoia ʻana i ka maikaʻi o ka mīkini a hoʻonui i ke ola o ka mea hana.

(1) Hoʻokomo i nā mea hana ʻoki

I ka hoʻoukaʻana i ka mea hana, he mea nui e hōʻoia i ka pololei o ke kūpono ma waena o ka mea hana a me ka mea paʻa, e hōʻoia i ka paʻa a me ka pololei o ka mea hana. I ka manawa like, pono e uku ʻia i ke kuhikuhi o ka hoʻonohonoho ʻana a me ke kūlana o nā mea hana e pale aku ai i nā hewa o ka hoʻonohonoho ʻana e hiki ai ke hana hewa a i ʻole nā mea hana.

(2) Ke koho ʻana i nā palena ʻoki no nā mea hana ʻoki

ʻO ke koho kūpono o ka ʻokiʻoki ʻana ke kī i ka hōʻoia ʻana i ka ʻoki maʻamau a hoʻonui i ke ola mea hana. ʻO nā ʻāpana ʻokiʻoki e pili ana i ka wikiwiki o ka ʻoki ʻana, ka nui o ka hānai, ka hohonu o ka ʻoki ʻana, a me nā mea ʻē aʻe, a pono e noʻonoʻo piha ʻia ma muli o nā kumu e like me ka mea paahana, mea hana mea hana, a me ka hana mīkini. ʻO ka ʻōlelo maʻamau, pono e koho ʻia i loko o ka ʻae ʻia o nā mea ʻoki ʻoki, nā wikiwiki ʻoki kiʻekiʻe a me nā uku hānai liʻiliʻi e hoʻomaikaʻi i ka maikaʻi o ka mīkini a me ka maikaʻi o ka ʻili.

(3) Hoʻoluʻu a lubrication o nā mea hana ʻoki

I ka wā o ka ʻoki ʻana, pono e hoʻohana ʻia nā ʻano hoʻoluʻu kūpono a me ka lubrication e hōʻemi i ka ʻoki ʻana i ka mahana, e hōʻemi i ka ʻaʻahu mea hana, a hoʻomaikaʻi i ka maikaʻi o ka ʻili mīkini. ʻO nā ʻano hoʻoluʻu maʻamau a me ka lubrication ʻo ia ka ʻoki ʻana i ka wai hoʻoluʻu, ka hoʻoluʻu ʻana i ka ea, ka lubrication ʻaila hinu, etc.

(4) Ka mālama ʻana a me ka mālama ʻana i nā mea hana ʻoki

Ma hope o ka hoʻomaʻamaʻa ʻana, pono e hoʻomaʻemaʻe ʻia nā ʻāpana a me nā ʻaila ʻaila ma nā mea ʻokiʻoki i ka manawa kūpono, a pono e nānā ʻia ka lole o nā mea hana. Inā loaʻa kekahi ʻaʻahu, pono e hoʻokala a hoʻololi ʻia i ka manawa kūpono. I ka manawa like, pono e hoʻokō ʻia ka mālama mau ʻana i nā mea ʻokiʻoki, e like me ka hoʻopili ʻana i ka aila hōʻoiaʻiʻo, ka nānā ʻana i ka pololei o ka mea paahana, a me nā mea ʻē aʻe, e hōʻoia i ka hana a me ke ola lawelawe o nā mea ʻoki.

7 、 Ka hopena

ʻO ke koho ʻana i nā mea hana ʻoki no nā mīkini wili CNC he hana paʻakikī a koʻikoʻi e pono ai ka noʻonoʻo piha ʻana i nā mea he nui e like me ka hana ʻana o ka mīkini, nā mea hana mea hana, nā papahana mīkini, a me nā helu ʻoki. ʻAʻole hiki i ke koho ʻana a me ka hoʻohana pono ʻana i nā mea ʻokiʻoki ke hoʻomaikaʻi wale i ka maikaʻi o ka mīkini a me ka hana ʻana i ka pono, akā e hōʻemi pū i nā kumukūʻai hana a hoʻonui i ke ola lawelawe o nā mea mīkini. No laila, i ka hana maoli, pono e koho ʻia ka mea hana kūpono e pili ana i ke kūlana kaʻina hana a me nā ʻano hana o ka mea hana, a e hoʻoikaika ʻia ka hoʻohana ʻana a me ka mālama ʻana i ka mea hana e hoʻohana pono i nā pono o nā mīkini wili CNC a hāʻawi i ke kākoʻo ikaika no ka hoʻomohala ʻana i ka ʻoihana hana.